Hygienic environments

Many industries, hospitals and laboratories require a controlled hygienic environment for their processes. In order to obtain a product or process of the right quality, an increased level of purity in the premises is required to filter out the particles and/or microorganisms. Control of differential pressure, temperature and humidity may also be required.

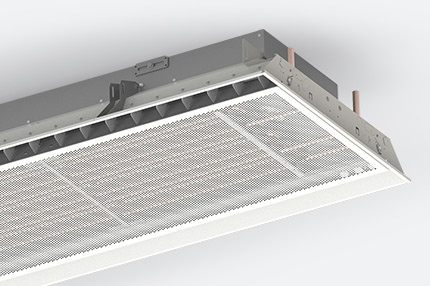

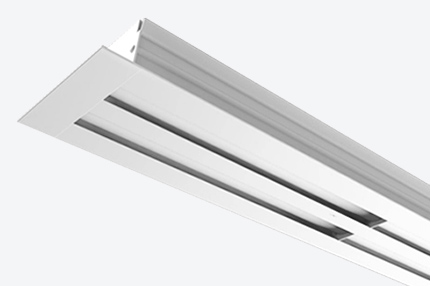

Clean rooms, laboratories and other industries (food, electronics, biotech, pharmaceutical) have the highest requirements for ventilation and air-conditioning systems. Because particles, germs, microorganisms, pollens in the outside air could have grave consequences on the indoor enviroment, the main objective is to prevent these from entering the workspace. Airvent offers specifically designed products ranging from clean room displacement diffusers, air volume controllers and air handling units, which fulfills these demanding requirements. With our demand-based automation solution we are also able to control and maintain the specified air pressure, air quality, temperature, humidity (RH), while monitoring the complete system through our SUM web app interface.

Header photo: Bert Leandersson

Airvent reference: Angered Hospital, Sweden