four-way air diffusion – for suspended ceiling application

PremiAir is designed for suspended ceilings where 360° air diffusion provides consistent comfort. It suits spaces from single offices to large areas such as shopping malls, conference halls, restaurants and schools. Available in sizes from 600×600 to 1800×600, PremiAir adapts easily to both small and large rooms. Adjustable nozzles allow on-site fine-tuning to balance airflow or avoid draughts, while the diffusion pattern can distribute air evenly in all directions or be set to specific room needs.

Its neutral design integrates discreetly into ceilings or can be supplied with a visible, powder-coated housing in most RAL colours. Flexible finishes and accessories make it equally suitable for educational facilities and high-end commercial interiors.

up to ~320 m³/h

600×600, 600×1200, 600×1800

Four-way air diffusion

Water (W) ~1500

At Δt=8.5, 100 Pa

PremiAir reference Project: Tura Group office; Location: Budapest, Hungary

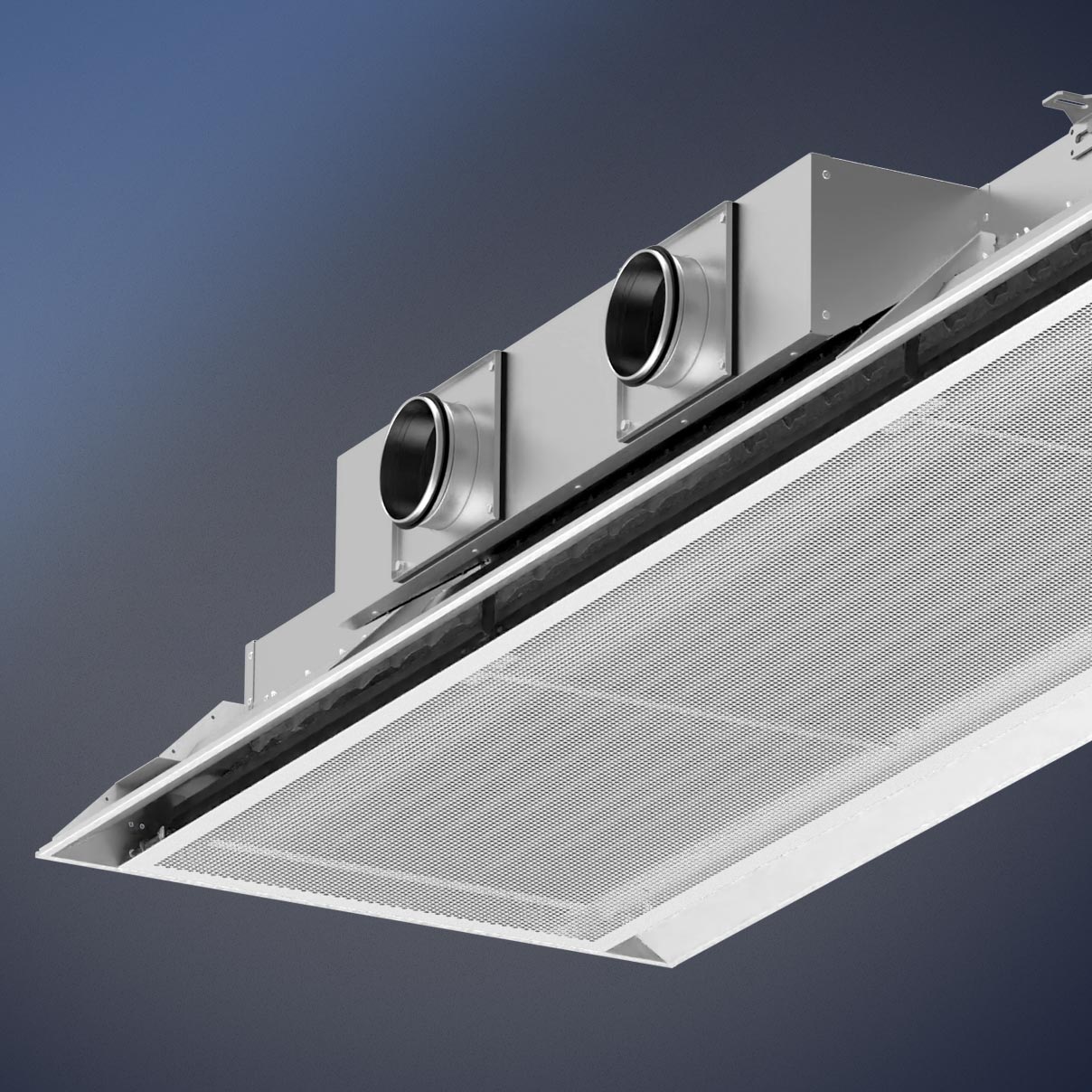

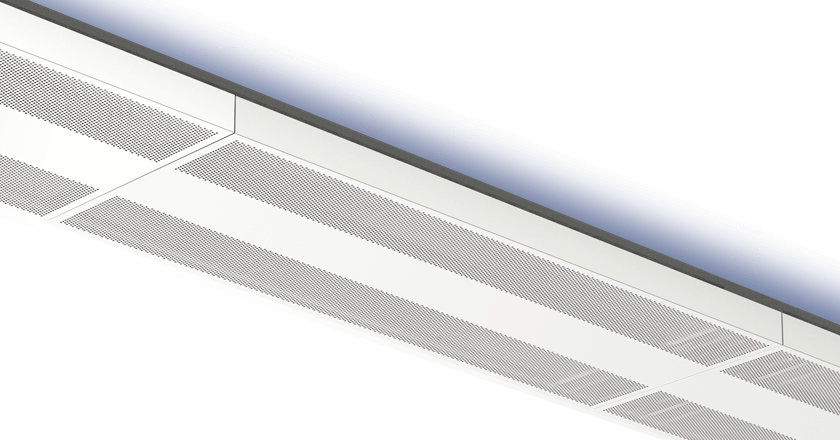

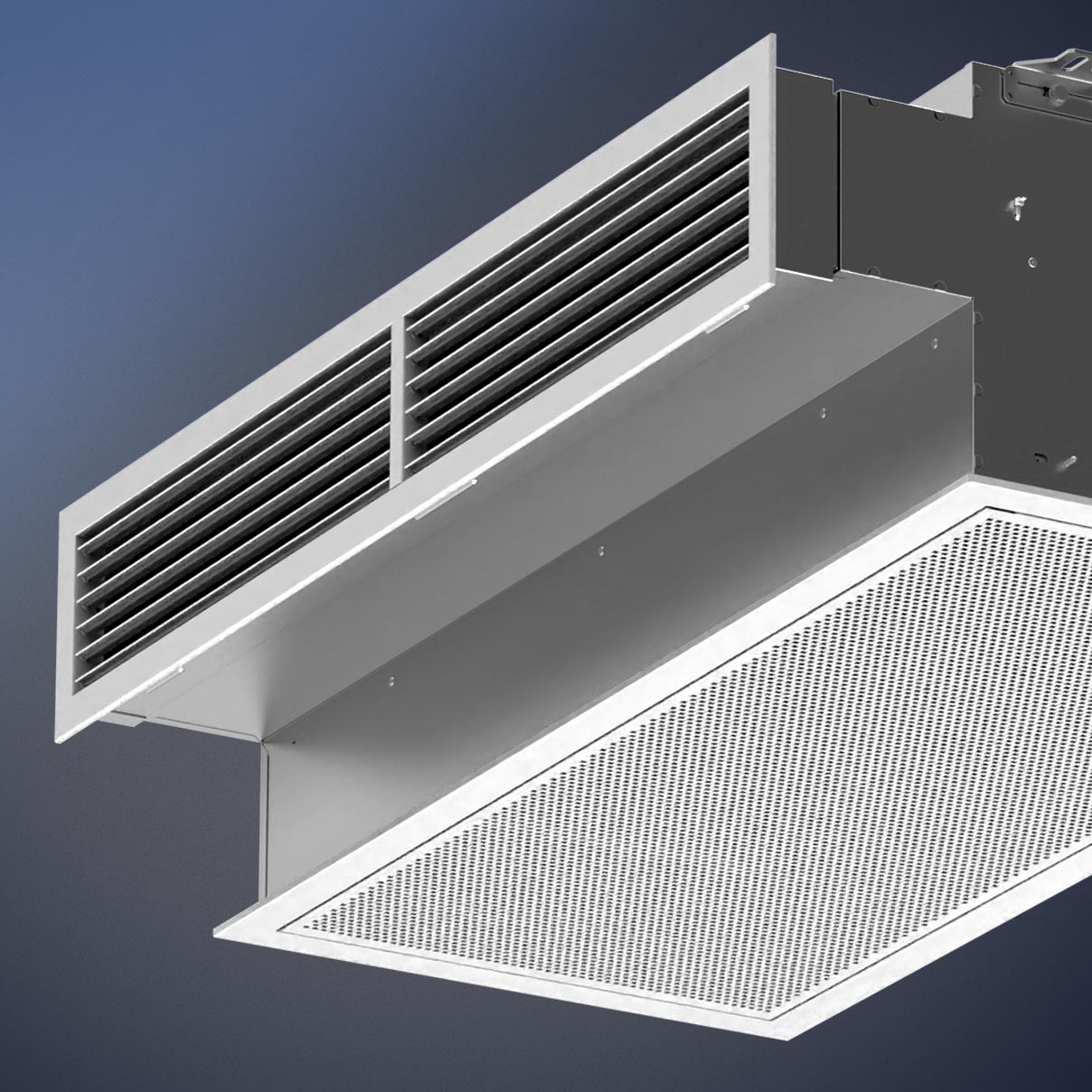

two-way air diffusion – for suspended ceiling application

AirFlex deflectors are included as standard and allow the air throw to be adjusted shorter or longer depending on the room geometry. Combined with adjustable nozzles, this makes it easy to fine-tune airflow on site and maintain draught-free comfort.

For visible installations, OptimAir can be supplied with Coanda frames or a powder-coated housing. With lengths ranging from 1200 mm up to 3600 mm, OptimAir provides a flexible solution for anything from compact rooms to large open-plan spaces.

up to ~320 m³/h

600×1200, 600×1500, 600×1800, 600×2100, 600×2400, 600×2700, 600×3000

Two-way air diffusion

Water (W): ~1740

at Δt=8.5, 100 Pa

The two- or four-way air diffusion options provide flexible distribution, ensuring maximum comfort without draughts, even in variable room layouts. Both models are ideal for offices, meeting rooms and open-plan environments where silent operation, low energy use and consistent indoor comfort are essential.

With adjustable nozzles and AirFlex deflectors, performance can be fine-tuned directly on site. The optimised heat exchanger capacity allows shorter unit lengths, reducing weight, installation footprint and transport volume – without compromising performance.

OptimAir reference Project: Nya Angared; Location: Malmö, Sweden

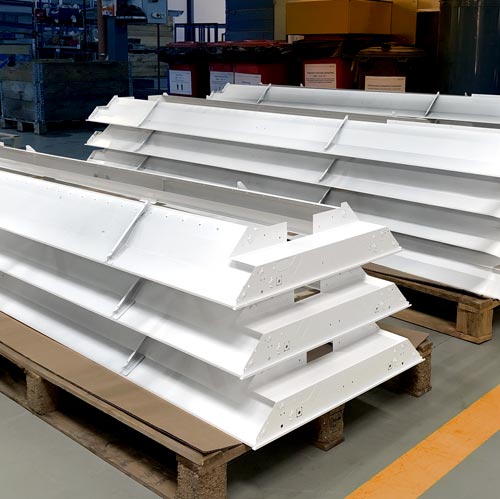

for exposed installation

Its compact, minimal design makes it suitable for refurbishments as well as new builds. FreeAir is widely used in modern office projects and educational buildings where an exposed installation is preferred for architectural reasons.

up to ~140 m³/h

1500, 1800, 2100, 2400, 2700, 3000

Two-way air diffusion

Water (W) ~1400

Δt=8.5, 100 Pa

FreeAir reference Office building Location: Lund, Sweden

for hotel applications

By using water as the main energy carrier and distributing air with high induction, HotelAir avoids draughts and ensures consistent comfort throughout the occupied zone for the guests. The design also simplifies maintenance for facility staff, with minimal servicing required over the product’s lifetime.

up to 140 m³/h

One-way air diffusion

Water (W): ~870

Δt=8.5, 100 Pa

HotelAir reference Project: Airvent Factory office; Location: Kecskemét, Hungary

Our chilled beams are designed to deliver comfort, efficiency, and flexibility. The table below highlights the key differences in our active chilled beam range to help you select the right solution.

PremiAir

PremiAir OptimAir

OptimAir FreeAir

FreeAir HotelAir

HotelAir¹ Bulkhead

² Coanda frame recommended

³ Adjustable aluminum fins

⁴ Environmental Product Declaration

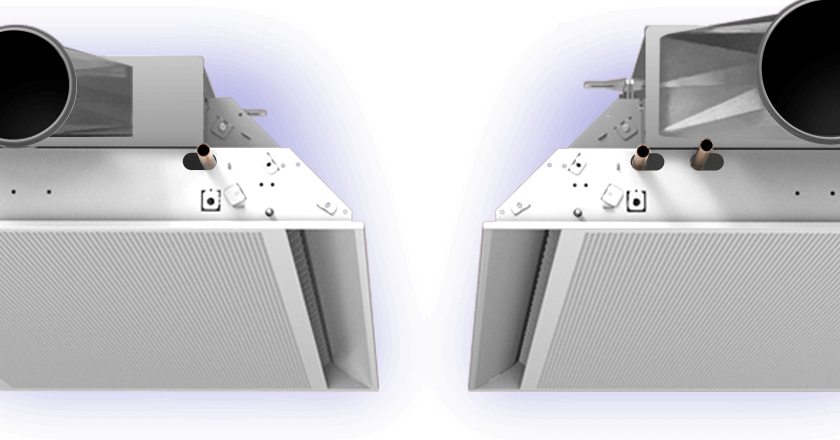

⌃ Nozzles of the PremiAir chilled beam – the unit is shown without the heating coil, air deflectors, and front panel.

As an option, Airvent chilled beams can be supplied with adjustable nozzles – a discreet, flexible, and popular solution for fine-tuning the primary airflow on site without altering system pressure. Each side of the plenum can be equipped with a row of individually adjustable nozzles, operated with a standard Allen key. Depending on the model, the flow rate can be set in multiple steps, either symmetrically or asymmetrically, to match the room layout and comfort requirements. By directing airflow away from sensitive zones, the risk of draughts is minimized and overall thermal comfort is improved. All settings can be configured in our selection software and factory pre-set, yet remain fully adjustable on site.

⌃ Air deflectors of the PremiAir chilled beam – the unit is shown without the front panel.

All active chilled beams come equipped with AirFlex deflectors as standard. These manually adjustable blades provide precise control of airflow direction and throw length on each side of the slots. AirFlex supports a wide range of diffusion patterns – from broad, short spread to focused, longer throws – adapting easily to room geometry and occupancy. When combined with adjustable nozzles, AirFlex enables a highly customisable indoor climate, optimised for both energy efficiency and occupant comfort

Key benefits:

Airvent’s chilled beam development is built on structured testing, engineering expertise, and long-term experience. Product design is continuously refined through in-house laboratory testing and simulation-based analysis, ensuring every solution meets the highest standards of quality, comfort, and performance.

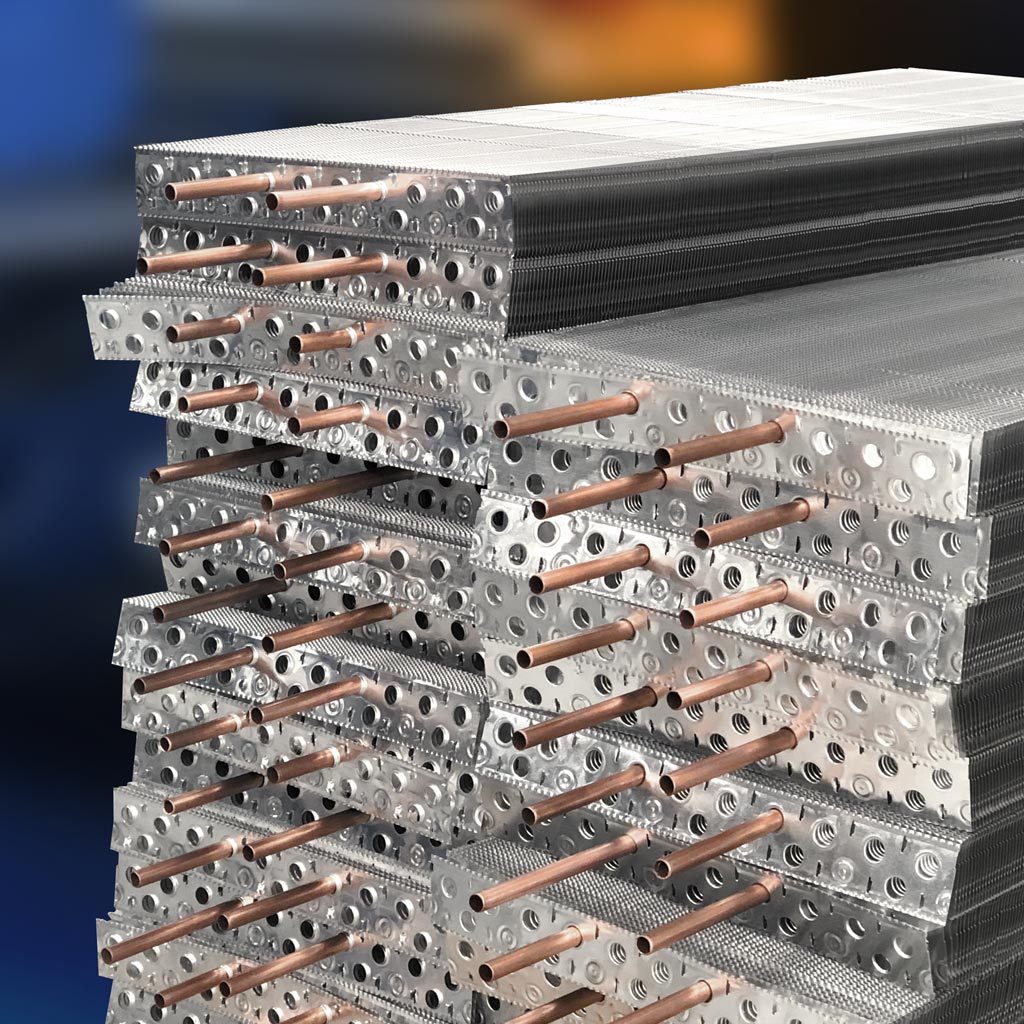

In our Swedish laboratory, each chilled beam type is tested for cooling and heating capacity, pressure drop, air velocity, and acoustic behaviour. These parameters are evaluated under controlled conditions to ensure predictable, stable performance in real applications. Acoustic testing is performed according to ISO standards, and key values are confirmed by independent third-party laboratories.

CFD is applied throughout the development process to study air discharge patterns at different temperatures, induction efficiency and thermal patterns. This helps us fine-tune nozzle geometries, diffuser frame design, and heat exchanger design before physical prototypes are built. Each detail is adjusted to avoid drafts, minimise noise, and maintain consistent comfort across different room types.

The heat exchanger in each chilled beam model is matched to the specific airflow and dimensions. This approach – rather than a one-size-fits-all solution – allows us to optimize energy use and ensure effective cooling or heating output across the full operating range. Nozzle shapes and positioning are likewise adapted to maintain stable induction and low sound pressure levels.

All performance data – including capacity, pressure drop, and sound – are documented and available in our selection software. This makes it easy for consultants and designers to dimension the system with confidence, and compare different product variants on a reliable technical basis.

Would you like to learn more about the operation, advantages, and different types of chilled beams? Visit the ReportAir blog to read our in-depth article “Operation and benefits of active chilled beams."

To the article→