What are the components of demand-controlled regulation and how do they operate?

CA-L3 controller

The control unit, together with its own 24VDC power supply, is housed in a plastic capsule that is connected to the sensors on the chilled beams. The housing can be placed freely on or near the chilled beam, depending on the installation characteristics (avoiding the ceiling service opening and other obstacles).

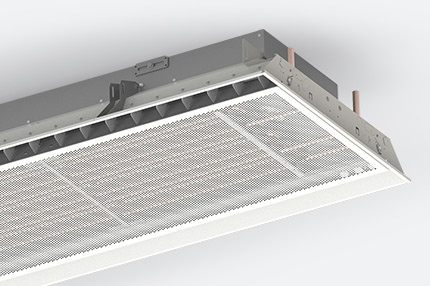

Integrated temperature and humidity sensors, built into the front panel of the chilled beam

Integrated temperature and humidity sensors, built into the front panel of the chilled beam

The CA-CB controller has room temperature and humidity sensors built into the perforated front panel of the chilled beam. The desired temperature can be set via a Modbus RTU-related BMS.

Wall temperature and humidity sensor with setpoint adjuster

Wall temperature and humidity sensor with setpoint adjuster

The Produal Proxima® RU-D-RH wall control unit has a built-in temperature and humidity sensor, as well as a setpoint adjuster and a digital display.

Temperature and humidity sensor built into the front panel of the chilled beam with a simple wall setpoint adjuster

Temperature and humidity sensor built into the front panel of the chilled beam with a simple wall setpoint adjuster

The CA-CB controller has room temperature and humidity sensors built into the perforated front panel of the chilled beam. The desired temperature can be controlled with the Produal Proxima® RU simple wall setpoint adjuster. Recommended for rooms where individual fine-tuning of the desired temperature value is required.

Pressure independent control valve for the water circuit

Pressure independent control valve for the water circuit

The CA-L3 controls the performance throught the water-side control valves, based on the temperature sensor and the pre-set temperature value. As a result of the Belimo® pressure-independent control valves, real-time cooling or heating capacity control can be achieved by properly pre-setting the minimum water flow required for efficient heat exchange.

Integrated motion sensors

Integrated motion sensors

In addition to the room temperature and humidity sensor built into the perforated front panel of the chilled beam, an optional 360° angle-sensing motion sensor with downward motion can also be integrated to distinguish between presence and absence modes. This option is ideal for presence-based ventilation of small office spaces (with chilled beams installed).

External motion sensor

External motion sensor

For larger rooms, an additional Regin® IR24-P external motion sensor can also be connected to the CA-L3 for visibility of the entire space.

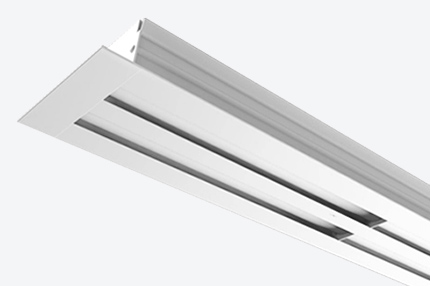

Open/close airflow control valve for chilled beams

Open/close airflow control valve for chilled beams

DUO is an airflow control valve with a unique damper blade, equipped with an on/off actuator as standard. When receiving a signal from a CA-L3 controller, the damper blade either opens completely when the zone or room is occupied, or closes in absent mode. When closed, the valve – through the special nozzle perforations on the blade – is still able to ensure very accurate and easily calculated airflows (depending on the chosen perforation type: A=10%, B=15%, C=20%, D=25% of the designed airflow), while securing low noise levels.

Window opening sensor

Window opening sensor

To save energy, the CA-L3 control unit can also be connected to a window opening sensor, which is set to disable cooling, heating or fresh air supply, if a window is opened.

Lighting control

Lighting control

Based on the signal of the motion sensor, we can distinguish between presence and absence modes, thus providing presence-based lighting control.